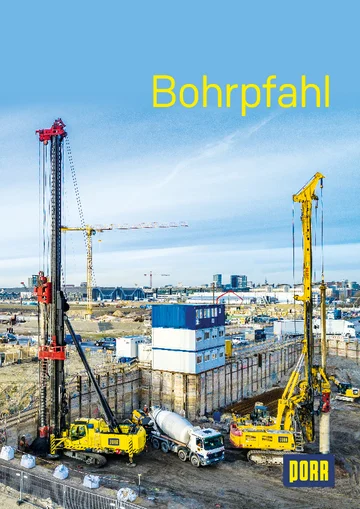

Bored piles

Encyclopedia: Bored piles

Bored pilesCompliant with DIN EN 1536

Bored piles are used as foundation elements where high loads must be transferred to deep, load-bearing soil layers. Soil is loosened and extracted during the pile manufacture. An entire pile volume’s worth of soil may be extracted during the process, or just part of it.

A well-known method used in specialist civil engineering is the bored pile, also known as the large bored pile. Bored piles are fabricated using rotary drilling rigs, hydraulic casing machines and specialist drilling equipment.

Our DIN EN 1536 compliant pile systems include:

- Bored piles

- Partial displacement bored piles (PDP)

- Continuous flight auger piles (CFA piles)

Hamburg Kasematten: Herstellung unter beschränkter Höhe im Greiferverfahren

© PORR

Applications

We use bored piles as deep foundation elements for all kinds of constructions.

Suitable projects include:

Bridges

Industrial buildings

Residential and commercial structures

Office buildings and hotels

Construction projects near sensitive areas or structures

These piles can be used in limited height conditions.

We can also arrange multiple bored piles in a line to create bored pile walls as a form of temporary construction pit system.

Advantages

Owing to the many possible variants, these piles can provide economically optimised solutions for every construction site situation and soil type.

The advantages of bored piles

- Bored piles can be fabricated with little noise and no vibration. This pile system is particularly suitable for foundation works in built-up areas and where neighbouring buildings are vulnerable to the effects of vibration.

- Bored pile dimensions can be tailored to suit high tensile and compressive loads. Moreover, large-diameter bored piles are resistant to bending and very well suited to taking horizontal strain.

- Gripper boring procedures with casing machines enable bored piles to be used in limited height conditions.

- Perpendicular piles and raking piles can be used at angles of up to 4:1.

- Piles can be bored straight through obstructions and hard soil layers.

- Equipment can be used flexibly for pile fabrication, enabling a variety of construction types including bored pile walls.

- They can even be used as energy piles, with the bored piles conducting geothermic energy.

The advantages of partial displacement bored piles (PDP)

- Small-diameter partial displacement bored piles can be quickly and economically installed with limited material consumption.

- In addition, the displacement effect ensures higher load bearing capacities than conventional bored piles.

- As the soil is partially displaced, this also reduces transport and disposal costs for the extracted cuttings.

- The reinforcement cage is constructed within the protection of the large hollow stem before concreting.

- This method can even be used for energy piles, with the PDP piles conducting geothermic energy.

- Perpendicular piles and raking piles can be used at angles of up to 4:1.

- These piles can be installed with no vibration and little noise.

The advantages of continuous flight auger piles (CFA piles)

- High drilling capacity makes these piles an economical choice.

- They are also suitable for pre-drilling through hard soil layers.

- These piles can be installed with no vibration and little noise.

Basic principles

Quality assurance

Quality assurance in construction work requires the observation of both European and national standards. The design and manufacture of bored piles are governed by Eurocode 7 and DIN EN 1536 and subject to the recommendations of the “Pfähle” working group (EA Piles). The self-monitoring and documentation of construction execution are also regulated by manufacturing standards.

Bored pile fabrication procedures must be individually tailored to the requirements of the specific method used. This requires specialist knowledge and experience in the field, together with sound instincts on the part of the machine operator. Large specialist machinery must be handled with sensitivity and due attention to the optimum adjustment of manufacturing parameters if the desired pile resistance is to be achieved.

We ensure high execution quality with:

- Individually tailored procedures

- Adherence to the requirements of DIN EN 1536, Eurocode 7 and EA Piles

- Clear processes overseen by our quality management system in accordance with DIN EN 9001:2005

- Static and dynamic pile loading tests

- Pile integrity tests