Sustainable solutions

Sustainable buildingClimate protection through smart processes

PORR pursues ambitious and clear goals in the area of sustainability and is gradually increasing the associated transparency. The basis for this is our comprehensive "Green and Lean" strategy, which is based on the three-pillar model of sustainability and takes all economic, environmental and social aspects into account. At PORR, these three central areas of sustainability are summarised under the term ESG (Environmental, Social, Governance).

Our focus is on active energy and emissions management, as well as resource-conserving and circular construction. In special civil engineering, we can make a significant contribution to sustainability in the construction industry throughlow-CO2 processes and numerous other measures. With our constantly evolving technologies, we contribute to mitigating the negative consequences of climate change and take current environmental issues into account in all our decisions. We work with you to develop sustainable solutions and assume ecological and economic responsibility.

Conserving resources starts in the planning phase

Sustainable planning is crucial for a significant improvement in theCO2 footprint during construction. In the later phase of construction pits and foundation work, we can only influence 5% of the causes of theCO2 footprint. Planning and preparation are therefore of the utmost importance.

We support you as early as the planning phase in selecting the optimum methods for the efficient use of construction materials and technology. As a full-service provider in special civil engineering, we select the method with the bestCO2 footprint from all the methods suitable for the construction project.

BrochureSustainability in special civil engineering

What you can expect in this brochure:

- Sustainable planning improves CO2 footprint

- Environmentally-friendly products and processes

- Optimised processes: Benefits thanks to Lean

- Resource-saving production

- More transparency: monitoring and documentation

- Certifications: Additional quality assurance

Sustainable applications

Sustainable construction site special civil engineeringSustainability certificate.

We support you right from the start if you are aiming for a sustainability certificate for your construction site. PORR Special Civil Engineering has been awarded the DGNB basic certificate ‘Sustainable Construction Site Special Civil Engineering’. Our sustainable standard construction processes already cover essential standards from the DGNB requirements catalogue for sustainable construction and serve as the basis for the certification of future PORR construction sites.

On request, we can manage your construction site in an environmentally friendly manner and with DGNB certification. The DGNB certificate offers you benefits for subsequent building certification and contributes to sustainable construction. External certification confirms our quality through neutral verification by a third party and gives you security.

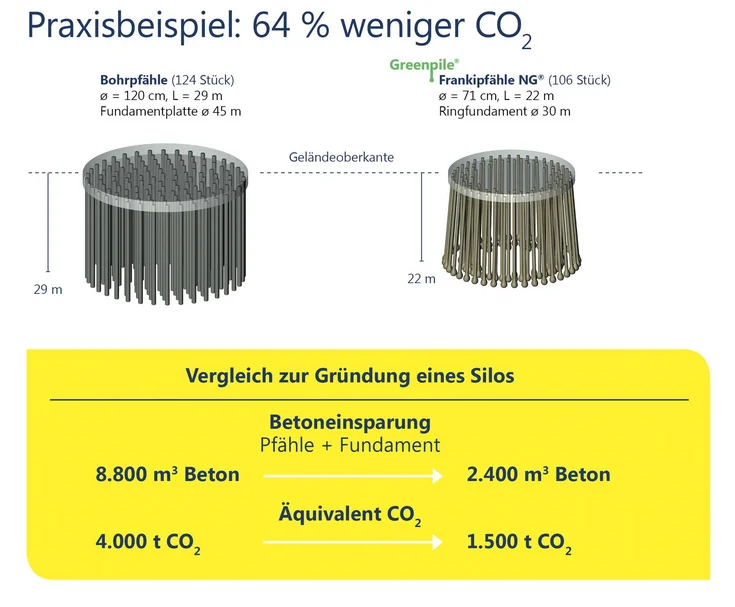

Example from practicefor the foundations of a silo

The cost savings andCO2 savings from foundation optimisation can be enormous, as the following project example illustrates. For the foundation of a silo in Wilhelmshaven with a total load of around 680 MN, we were able to convince the client to opt for deep foundations on Frankipile NG® piles. We can also plan your excavation project economically and ecologically from the ground up or optimise it accordingly - for example by replacing classic jet grouting with soft gel injection grouting with bio-soft gel, without the use of cement.